Turret

Load Handlers

Specific solutions for load handling

Specific solutions for different load handling requirements. Load handlers vary greatly in design – function – and capacity. The Load Handling unit is not the only consideration when designing your specific vehicle.

In order to manufacture the vehicle to endure many years of service, the cab, auxiliary mast, mast and chassis should be considered as an integral part of the solution. Let your system “professionals” assist you and offer a custom built solution to enhance your operation.

Standard Turret

The 180 degree rotating fork handler is an integral part of the forklift as opposed to a separate attachment. The entire vehicle is designed around the load to be handled along with the size of the working aisle. The cab, integrated load handler, mast and chassis form a comprehensive handling solution.

- Load aisles range from 47″ to 120″

- Load widths from 30″ to 124″

- Load insertion sizes range from 32″ to 96″

Large Loads

Load widths may not be uniform, but with the variable sliding fork carriage they no longer pose a problem:

Instead of building a vehicle to suit the widest load size and increasing the overall vehicle length utilize a sliding fork carriage. The vehicle can handle larger oversize load widths while allowing for order picking from standard pallet widths. A fork positioner allows the handling of various size loads – with a larger load handler.

MSG 320

The standard turret moves from side to side via the integrated hydraulic torque motor. The rotation of the fork carriage is controlled via opposing pistons.

There are two basic auxiliary mast heights to choose from 67″ & 90.5″. These dimensions are additional to the main mast lift.

Special heights or requirements are never a problem such as handling oversized loads or integrating a hydraulic fork positioner.

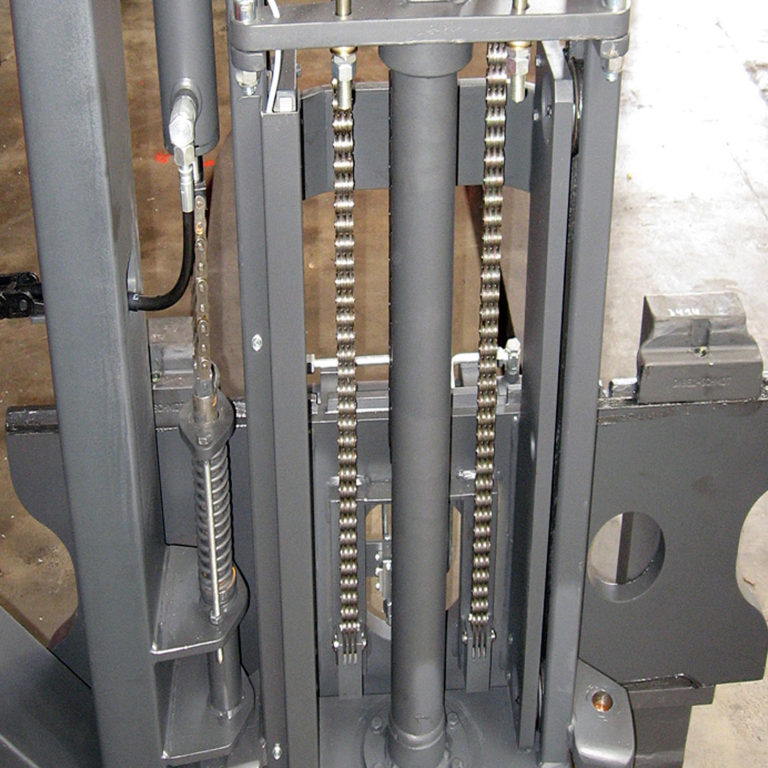

MSG 120

The heavy duty series turret style features connection to the mast and cab in multiple strengthened locations. MSG 120 turret style handler with wider auxiliary mast, dual lift chains and when required center guide rail, delivers optimum performance with heavy loads.

Additional features can be found on the 4400 lb HL series with hydraulic mechanical rotation locks and strengthened supports such as the double deep load handler based on the MSG 120 turret.

Telescopic Fork

Telescopic forks are designed to handle open faced skid or single sided pallets such as the Euro Pallet. The design eliminates the need to rotate the load in the narrow aisle by inserting the load to either side.

Advantages include decreased cycle times and a working in an aisle only 8″ wider than the load insertion.

Limitations require the use of P&D (Pick & Deposit) stations as well as lower rack beam level or a raised rack pedestal.

Consult your local Sales Representative for comprehensive comparisons.

Double Deep

High density storage for slower moving product. Double deep storage available to 50′ where the operator rides up with the load. Compare the cost saving storage and vehicle features against a double deep reach truck.

Provides a solution for dense storage in very narrow aisles.

The heavy duty EK series is more than capable of handling loads in a double deep pallet environment. The operator has the advantage of riding up with the load – can view the forks / load even in the second row. Note the optional top rail support for added capacity at elevation.