Maintenance

Reliability & Repairs

Ease of maintenance

The service on very narrow aisle turret trucks should offer expedited trouble shooting and cost effective repairs. These vehicles often provide the only method to obtain goods from a high bay storage areas and downtime is considered critical. The modular approach of the electronic and hydraulic components serves to simplify the service and minimize any downtime.

Modular open system for cost efficiency

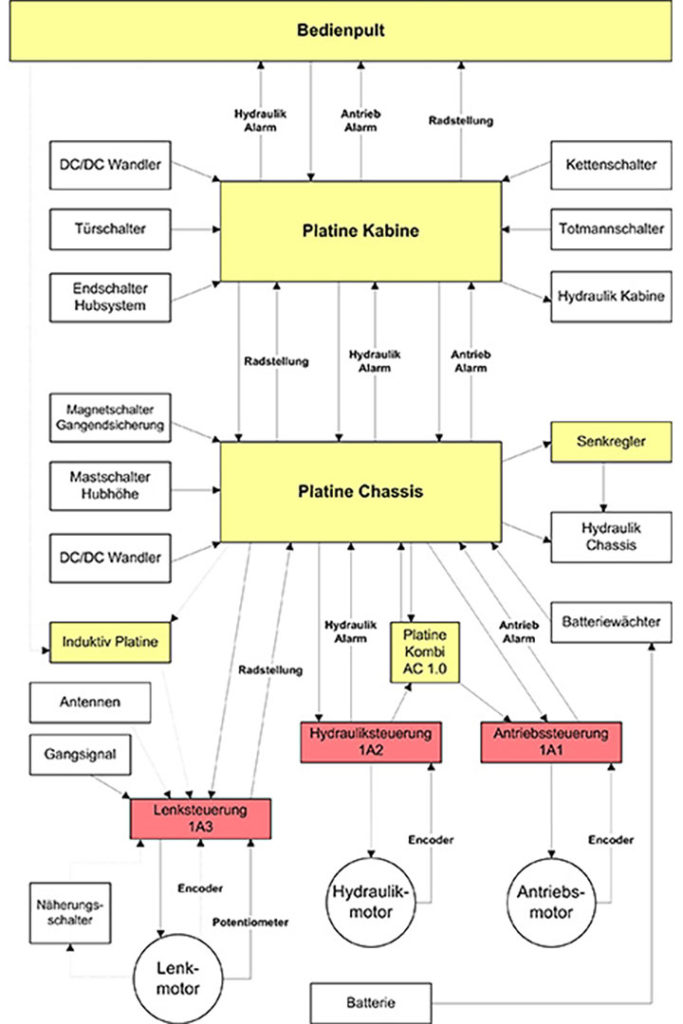

The EK-Series electronic system consists of a network of two electronic interface boards and three performance based controllers, hydraulic, travel, and steering all communicating via CAN-bus technology. Due to this open system architecture a flexible parameterization of all functions and a rapid replacement or upgrade of modules are guaranteed. Various diagnostic methods are available to the service technician:

- LED display – vehicle mounted

- CAN-Bus connection for diagnostic reader

- USB connection for laptops and notebooks

- GSM connection for remote diagnostics

In order to afford customers and their selected maintenance technicians the ability to service the equipment on their terms, the diagnostic and control specific software is not proprietary license protected.

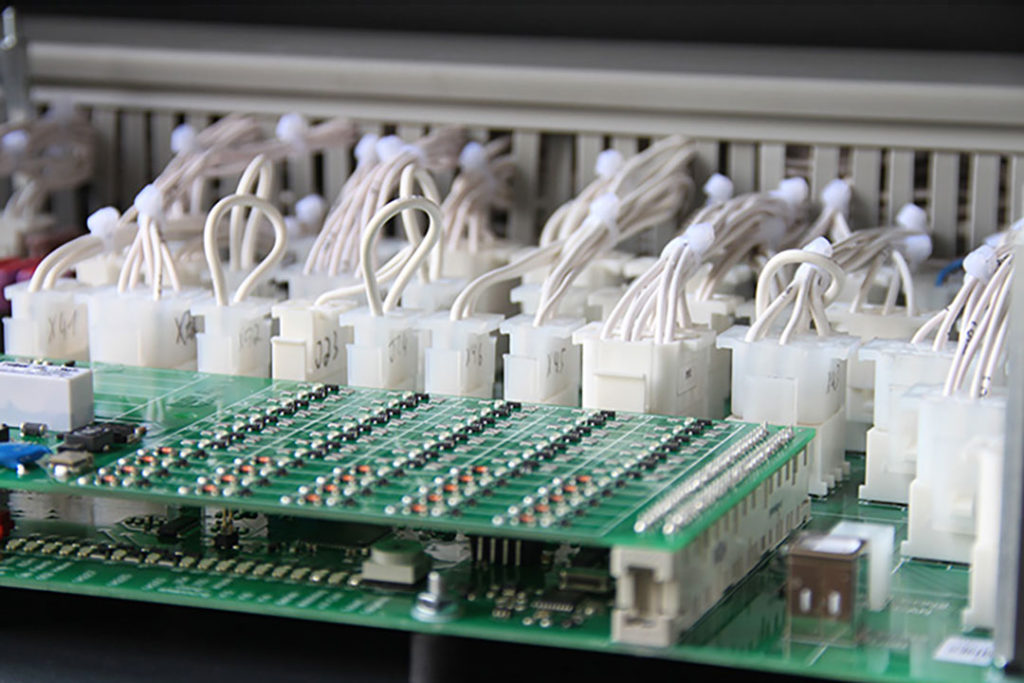

Quick access to components for rapid service

To ensure maximum throughput, equipment downtime must be held to a minimum. The EK-Series motor compartment is clean (no carbon dust from motor brushes) and conceptually laid out to assist the technician – interface board and diagnostic at waist level, all around access to the electronic and hydraulic system. Components can easily be exchanged if required. Even the cabin interface board is accessible via the USB port without having to remove it. Our well trained service partners know the trucks like the back of their hand and guarantee well working machines at all times.